沃尔玛验厂

一. 简介 沃尔玛目前要求所有的供应商在通过沃尔玛验厂的标准后才可以向其供货。目前,沃尔玛验厂可以分为三个部分: 1.)质量验厂(FCCA):也叫技术验厂,或者品质验厂。主要针对工厂生产产品的生产水平做一个综合评估。 2.)人权验厂(ES):也

- 性质: FCCA质量验厂

- 品牌: walmart 沃尔玛

- 价格:

- 备注:

一. 简介 沃尔玛目前要求所有的供应商在通过沃尔玛验厂的标准后才可以向其供货。目前,沃尔玛验厂可以分为三个部分: 1.)质量验厂(FCCA):也叫技术验厂,或者品质验厂。主要针对工厂生产产品的生产水平做一个综合评估。 2.)人权验厂(ES):也

沃尔玛目前要求所有的供应商在通过沃尔玛验厂的标准后才可以向其供货。目前,沃尔玛验厂可以分为三个部分:

1.)质量验厂(FCCA):也叫技术验厂,或者品质验厂。主要针对工厂生产产品的生产水平做一个综合评估。

2.)人权验厂(ES):也叫社会责任验厂,或者ES人权验厂。主要针对工厂员工工资福利、消防、工作条件等方面进行的评估。

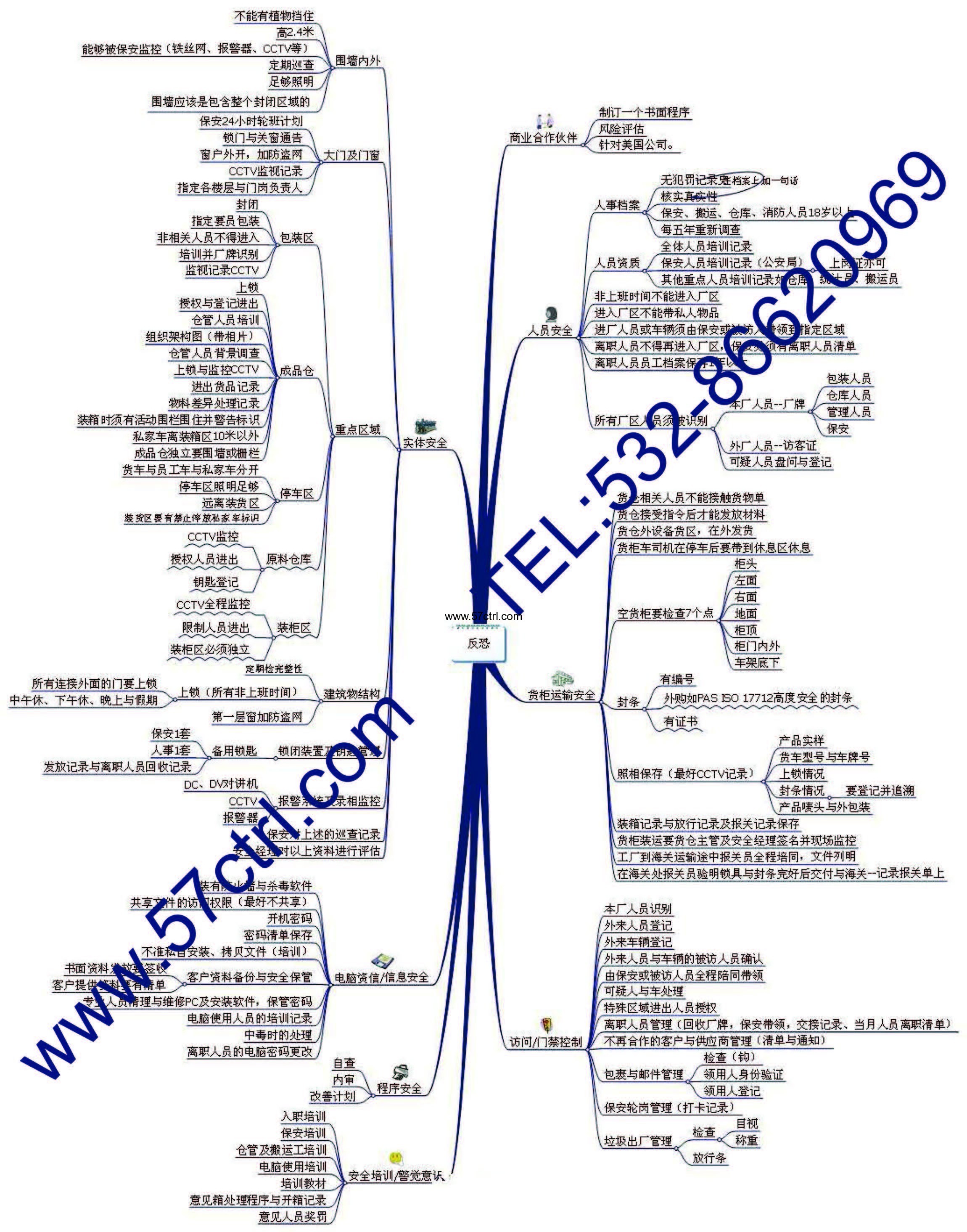

3.) 反恐验厂(SCAN): 也称GSV验厂,或者C-tpat验厂。SCAN主要针对15年后新加入的沃尔玛供应商厂家。

| No. | 沃尔玛FCCA品质验厂项目与内容 Items | YES | NO | N/A |

| 1.0 | 工厂自我评估表 Wal-Mart Factory Pre-Audit Questionnaire | ⃐ | ⃐ | ⃐ |

| 1.1 | 工厂简介 Brief introduction of factory | ⃐ | ⃐ | ⃐ |

| 1.2 | 营业执照 Business license | ⃐ | ⃐ | ⃐ |

| 1.3 | 公司组织架构图 Organization chart | ⃐ | ⃐ | ⃐ |

| 1.4 | (公司)厂区/厂房平面图 Factory’s plane figure-factory floor plans | ⃐ | ⃐ | ⃐ |

| 1.5 | 生产工序流程图 Production process chart | ⃐ | ⃐ | ⃐ |

| 1.6 | 管理系统证书 (质量/环保/社会责任等) Certificate of various management systems ISO9001/ ISO14001/ ICTI/ GSCP, etc. | ⃐ | ⃐ | ⃐ |

| 2.1 | 虫鼠控制/防潮防霉控制程序(制度)及记录 Documented pests/mildew and moisture control program | ⃐ | ⃐ | ⃐ |

| 2.2 | 利器 (刀片,断针等) 收发控制/断针控制/验针记录 Procedure and records of sharp tools control/broken needle control/metal detection | ⃐ | ⃐ | ⃐ |

| 3.1 | 仪器设备校验程序/记录和报告 Procedure and records of equipment calibration | ⃐ | ⃐ | ⃐ |

| 3.2 | 设备(生产机器检验设备/工具/备件)清单 List of machines, tools, spare parts and equipments | ⃐ | ⃐ | ⃐ |

| 3.3 | 设备维修保养记录Maintenance and repairing records for machine/equipment. | ⃐ | ⃐ | ⃐ |

| 4.1 | 质量手册 (质量方针/目标)/ 程序文件 Quality manual/ procedures | ⃐ | ⃐ | ⃐ |

| 4.2 | 客户投诉处理程序及记录 Procedure and records of customer complaint | ⃐ | ⃐ | ⃐ |

| 4.3 | 产品紧急事故处理程序(包括召回程序)及记录 Recall program including procedure and records when applicable | ⃐ | ⃐ | ⃐ |

| 4.4 | 品管组织架构图 Organization chart of QMS/QC | ⃐ | ⃐ | ⃐ |

| 4.5 | 质量管理体系/控制关键人员职责 Role and Responsibility of QC personnel | ⃐ | ⃐ | ⃐ |

| 4.6 | 定期不定期质量管理体系/控制会议的机制及记录 Mechanism and records of regular/ irregular review/meeting on QMS/QC | ⃐ | ⃐ | ⃐ |

| 4.7 | 潜在危害风险评估(物理异物如金属, 玻璃等/化学/微生物方面的危害) Risk assessment to identify hazards from chemicals/ raw materials/ process/ equipment and tools | ⃐ | ⃐ | ⃐ |

| 4.8 | 控制(生产及产品受物理异物/化学/微生物等)污染风险的控制程序及记录(可能对 产品或人造成伤害) Procedures and records about control risk of physical/chemical/biological contamination (which may damage the product and personnel) | ⃐ | ⃐ | ⃐ |

| 5.1 | 来料检验控制程序 Procedure of quality control on incoming materials | ⃐ | ⃐ | ⃐ |

| 5.2 | 各种来料检验标准及缺陷分类 Inspection criteria (e.g. sampling plan/ AQL/ defective classification) | ⃐ | ⃐ | ⃐ |

| 5.3 | IQC来料检验报告/ 不良品处理(退货,挑选及让步接收等)记录 Inspection/test reports of incoming materials including rejected items and concession when applicable. | ⃐ | ⃐ | ⃐ |

| No. | 项目与内容 Items | YES | NO | N/A |

| 5.4 | 来料中免检产品的符合性证书或测试报告Certificate of compliance or test report of incoming materials when applicable. | ⃐ | ⃐ | ⃐ |

| 5.5 | 物料库存/周转控制的程序或规定 Procedure/rules of materials rotation control and inventory management warehouse (e.g. FIFO) | ⃐ | ⃐ | ⃐ |

| 5.6 | 供应商评审程序及记录 (包括初次供应商挑选批准评估及后续定期的供应商表现 评估) Supplier Assessment System (including initial evaluation and regular assessment) | ⃐ | ⃐ | ⃐ |

| 5.7 | 供应商来料状况统计 KPI of ongoing performance | ⃐ | ⃐ | ⃐ |

| 6.1 | 产品设计程序及记录 (适合时) Procedure and records of product design when applicable | ⃐ | ⃐ | ⃐ |

| 6.2 | (量产前进行)试产的制度记录及相应的纠正改善措施(有需要时 Mechanism of pilot-run and the corresponding CAP when applicable) | ⃐ | ⃐ | ⃐ |

| 6.3 | 产前会议制度及记录 Procedure/records of pre-production meeting | ⃐ | ⃐ | ⃐ |

| 6.4 | 制造各工序包括包装的作业指导书/规格要求, 参考样板, 批准板, Working instruction/ specification/ approval and reference sample for manufacturing and packing | ⃐ | ⃐ | ⃐ |

| 6.5 | 过程质量控制的程序/标准/记录 (首件检验,在线检验,巡检,抽检, 全检,批次检 验) Procedure/criteria/ records of IPQC (First piece inspection, on- line inspection, routine inspection, random inspection, full inspection, ,lot inspection, etc.) | ⃐ | ⃐ | ⃐ |

| 6.6 | 过程不良处理机制及记录 Procedure of non-conformance control during manufacturing | ⃐ | ⃐ | ⃐ |

| 6.7 | 过程不良的纠正预防 CAP in case of rejected products/lots of semi- products | ⃐ | ⃐ | ⃐ |

| 7.1 | 终检验程序(可能多种形式, 叫法也可能不同)包括FQC或OQC或QAProcedure of final inspection (e.g. FQC/OQC/QA) | ⃐ | ⃐ | ⃐ |

| 7.2 | 终检验标准(可能多种形式, 叫法也可能不同)包括FQC或OQC或QA Inspection criteria/ specification and reference sample/ records of final inspection | ⃐ | ⃐ | ⃐ |

| 7.3 | 成品不良处理机制及记录 Procedure of non-conformance control of finished products | ⃐ | ⃐ | ⃐ |

| 7.4 | 成品不良的纠正预防 CAP in case of rejected products/lots | ⃐ | ⃐ | ⃐ |

| 7.5 | 成品出货放行机制 Procedure of shipment release | ⃐ | ⃐ | ⃐ |

| 7.6 | 标识及可追溯性:批次标识/日期标 Identification and traceability (batch code/date code, etc when applicable) | ⃐ | ⃐ | ⃐ |

| 8.1 | 内部测试清单/ 测试手册(操作指引)/ 测试记录 List of in-house testing/ testing manual / testing records | ⃐ | ⃐ | ⃐ |

| 8.2 | 仪器校验记录 Calibration of testing equipment | ⃐ | ⃐ | ⃐ |

| 8.3 | 测试人员资质培训记录 Training records of testing technician | ⃐ | ⃐ | ⃐ |

| 9.1 | 培训的机制及记录 (包括入职前, 岗前培训, 定期培训, 包括普通操作员/检验员 /工程技术人员) Training procedure and records (pre-work training, on- job training and regular training) for workers/ QC members/ technician/ engineers | ⃐ | ⃐ | ⃐ |

| 9.2 | 对熟练工技术人员的招聘前的考核Pre-hire test for skilled personnel | ⃐ | ⃐ | ⃐ |

| 备注 REMARK | 在现场抽查与公司生产运作有关的任何其它相关文件与记录⃞谢谢支持和合作. Some other documents/records may be required during on-site audit based on FCCA requirements and actual situation. Thanks for your support and cooperation in advance. | |||

| 沃尔玛社会责任审核文件清单 | ||||

| No. | Wal-Mart RS Audit Document List 沃尔玛社会责任审核文件清单 | Yes | No | N/A |

| 1 | Floor Plan / Production Process Flow Chart 厂区平面图层工艺流程图 | |||

| 2 | Business License 营业执照 | |||

| 3 | Name List of Employees 员工花名册 | |||

| 4 | Payroll Records 最近12个月的工资记录 | |||

| 5 | Attendance Records 对应以上12个月工时记录 | |||

| 6 | Comprehensive Working Hour System Approval 综合计时批文 | |||

| 7 | Payment Receipt of Social Insurance Schemes 最近12个月社保缴费收据及人数/名单 | |||

| 8 | Records of Paid Annual Leave 有薪年假记录 | |||

| 9 | Factory Regulations 厂规或员工手册 | |||

| 10 | Employment Registration Records 员工入职登记表 (附身份证复印件) | |||

| 11 | Labor Contracts 劳动合同 | |||

| 12 | Leave Appliactions 员工请假表 | |||

| 13 | Health Examination / Registration of Juvenile Workers 未成年工体检证明层劳动部门登记 | |||

| 14 | Trade Union / Worker Organization 工会委员会名单层章程层会议记录 | |||

| 15 | Occupational Disease Hazard factors tests 车间职业健康危害因素监测报告 | |||

| 16 | Occupational Disease Examination Records 职业健康检查/体检报告 | |||

| 17 | MSDS / Inventory for Hazardous Substances/Chemicals 危险物质层化学品名录及物质安全资料表 | |||

| 18 | Chemical Contral Program / Training Record 化学品管控程序 / 培训记录 | |||

| 19 | Hazardous Chemicals Spill Response Drill Record 危险化学品泄露应急演练记录 | |||

| 20 | Report of inspection for completed building construction projects 建筑工程竣工验收报告 | |||

| 21 | Certificate of Inspection for Completed Building Construction Projects 建筑工程竣工验收备案证 | |||

| 22 | Fire Control Acceptance Check 消防验收 | |||

| 23 | Zoning Permit 建设工程规划许可证 / 建设用地规划许可证 | |||

| 24 | Accident / Incident Record 工伤记录 | |||

| 25 | Safety Documents for Special Equipments 特种设备档案 (电梯层锅炉层压力容器层厂内机动车层起重机等登记证和定期安检报告) | |||

| 26 | Work Permits for Special & Dangerous Operations 特种作业工操作证 (电工层焊工层锅炉工层压力容器操作工层厂内机动车操作工层起重机工等) | |||

| 27 | Hygiene Certificate for the Canteen 员工食堂餐饮服务许可证 | |||

| 28 | Health Certificate of Food Operators 食堂员工健康证 | |||

| 29 | Subcontractor Information 外发商层分包商信息 (厂名层地址层联系人层电话层工序) | |||

| 30 | Production Record 生产记录 (日报表层仓库收发记录层QC检查记录等) | |||

| 31 | Environmental impact appraisal documents 环境影响评价文件 (环评登记表层报告表层报告书,环评批复,环保竣工验收) | |||

| 32 | Hazardous Waste Disposed Document 危险废物处置文件 (危废处置商资质证明层危废处置合同层危废转移联单) | |||

| 33 | Emvironmental Policy 环保政策 | |||

| 34 | Discharge Permits 排污许可证 (生产废水层工业燃烧锅炉) | |||

| 35 | Wastewater Discharge / Air Emission Invertory and Monitoring Report 生产废水排放清单 / 废气排放清单,监测报告 | |||

| 36 | Wastewater Drainage Plan 排水管网平面图 | |||

| 37 | GHG Inventoty 温室气体排放清单 | |||

| 38 | ODS Inventory 破坏臭氧层气体物质排放清单 | |||

| 39 | Energy Consumption Records 能源消耗清单 (水层电层燃气层燃油) | |||

| 40 | Emergency Evacuation Plan 紧急疏散平面布置图以及疏散计划 | |||

| 41 | Emergency Action Plan Training Record 紧急疏散培训记录 (入职培训层日常培训) | |||

| 42 | Assignment/Training Documents of Emergency Response Personnel 应急响应负责人任命书及培训记录 | |||

| 43 | Hazardous/Combustible/Flammable Materials Handling Training Record 危险品层易燃物层可燃物操作培训记录 | |||

| 44 | Fire Drill / Evacuation Drills Record 消防演习 / 紧急疏散演习 | |||

| 45 | Fire Equipment Inspection Record 消防器材定期检验记录 (内部检查层外部检查) (灭火器层室内消防栓层火灾自动灭火系统层消防水池水位层消防水泵) | |||

| 46 | Electrical Wiring Inspection Program/Record 电气安全定期检查程序及记录 | |||

| 47 | Fire Safety Committee O-Chart 消防安全委员会组织架构图 | |||

| 48 | Fire Safety Committee Meeting Record 消防安全委员会会议记录 | |||

scan反恐要求

请点击![]() 2016沃尔玛人权验厂中国地区常见高风险违规情况.pdf下载。

2016沃尔玛人权验厂中国地区常见高风险违规情况.pdf下载。